Understanding Rapid Prototype Manufacturing

Rapid prototype manufacturing is an innovative approach that leverages cutting-edge technologies to streamline product design and reduce the time to market. In the realm of metal fabrication, this process holds significant potential to revolutionize how manufacturers create and test new components.

What is Rapid Prototype Manufacturing?

At its core, rapid prototype manufacturing involves the quick fabrication of a physical model or prototype using computer-aided design (CAD) data. This technique allows engineers and designers to iterate their concepts swiftly, resulting in a more efficient design cycle. The main goal is to identify flaws and improvements long before full-scale manufacturing begins.

Techniques Used in Rapid Prototype Manufacturing

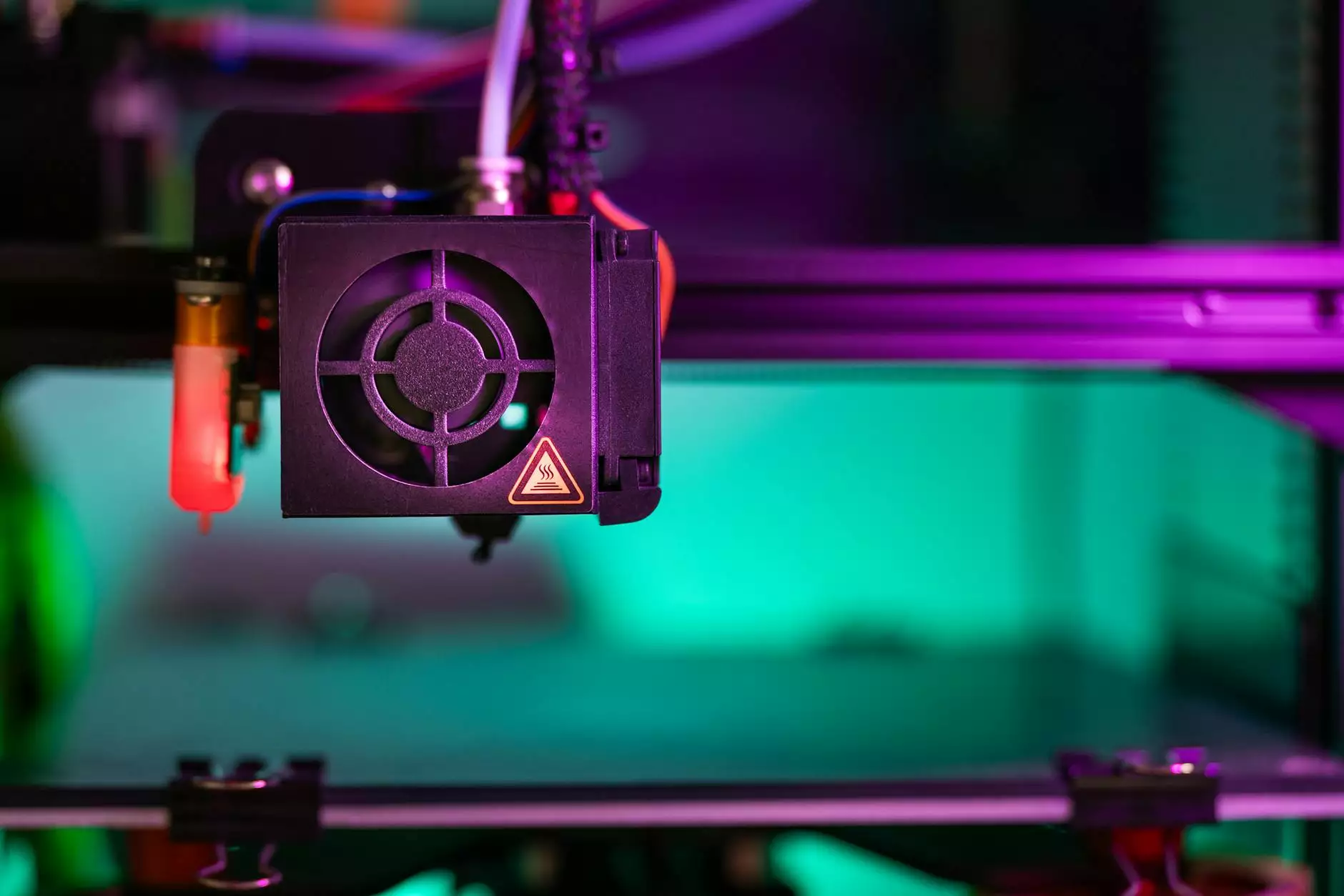

- 3D Printing: A versatile option that allows for complex geometries and quick iterations.

- CNC Machining: Ideal for precision parts, CG machining can quickly produce prototypes from various metals.

- Sintering: This process is essential for certain materials, ensuring durability and performance in the final product.

The Importance of Rapid Prototypes in Metal Fabrication

In the field of metal fabrication, the importance of rapid prototype manufacturing cannot be overstated. It provides a tangible means of evaluating form, fit, and function quickly and effectively. By utilizing prototypes, businesses can:

Benefits of Rapid Prototyping in Metal Fabrication

- Shorten Development Time: The design phase can see substantial time reductions, enabling quicker market entry.

- Cost Efficiency: Early detection of design flaws reduces costs associated with revisions in later stages.

- Enhanced Collaboration: Stakeholders can visualize and interact with prototypes, improving communication throughout development.

- Fostering Innovation: Rapid prototyping encourages experimentation with new ideas without significant investment.

Applications of Rapid Prototype Manufacturing

The applications of rapid prototype manufacturing in the metal fabrication sector are diverse and impactful. Here, we explore some of the primary areas where this technology is making waves:

1. Aerospace and Automotive Industries

The aerospace and automotive sectors require highly intricate and reliable components. Rapid prototyping allows manufacturers to develop parts that meet stringent safety and functionality standards. Designers can test multiple variations of a single component, leading to optimal performance.

2. Medical Devices

Rapid prototypes allow for the swift assembly and testing of instruments crucial for patient care. Speedy development benefits from rapid prototyping, ensuring that vital healthcare solutions are available promptly and efficiently.

3. Consumer Products

From kitchen gadgets to electronic devices, manufacturers can use prototypes to evaluate user experience and product ergonomics. Rapid prototyping can significantly enhance the consumer feedback loop, leading to improved designs.

Challenges Facing Rapid Prototype Manufacturing

While rapid prototyping offers numerous advantages, it is not without its challenges. A few notable issues include:

Cost of Technology

The initial investment in rapid prototype manufacturing technology, especially advanced 3D printers and CNC machines, can be high. However, the long-term savings often outweigh these costs.

Material Selection

Choosing the right materials for prototypes is crucial. Not all metals behave the same way under various manufacturing processes, which can affect the outcome of the prototype.

Skill Gap

As technologies advance, there is a growing need for skilled personnel familiar with rapid prototyping processes. Training and upskilling become essential for companies aiming to stay competitive.

Future Trends in Rapid Prototype Manufacturing

The future of rapid prototype manufacturing looks promising, with several trends shaping its evolution:

1. Integration of AI and Machine Learning

Artificial intelligence and machine learning can optimize design processes by predicting potential issues, thus minimizing trial and error in prototyping.

2. Advanced Materials

Research into new materials, including composites and smart materials, is already underway. As these materials become more widely available, their adaptability and functionality in prototypes will expand.

3. Sustainability Focus

With increasing awareness of environmental issues, the metal fabrication sector is moving towards sustainable practices. Rapid prototyping can facilitate the use of recyclable materials, reducing waste in the manufacturing process.

Why Choose DeepMould for Rapid Prototype Manufacturing?

At DeepMould.net, we specialize in cutting-edge rapid prototype manufacturing techniques tailored to the unique needs of our clients. Here are several reasons why you should consider us for your next project:

- Expertise: Our team has years of experience in metal fabrication and rapid prototyping, ensuring high-quality results.

- State-of-the-Art Technology: We utilize the latest in 3D printing and CNC machining technologies, resulting in precision and reliability.

- Customization: We understand that every project is unique; hence we offer personalized solutions that fit your requirements.

- Commitment to Quality: Our rigorous quality assurance processes ensure that your prototypes meet all specifications before fabrication begins.

Conclusion

The landscape of metal fabrication is evolving rapidly with the advent of rapid prototype manufacturing. This approach not only enhances efficiency but also fosters innovation, allowing manufacturers to stay competitive in a fast-paced market. Embracing this technology ensures that your business is better positioned to meet the demands of what lies ahead. At DeepMould.net, we are committed to helping you harness the advantages of rapid prototyping to effectively bring your ideas to life.

Don't hesitate to contact us today to learn how we can support your next project with our exceptional prototyping services.